WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Manufacturing - the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the burner being lower.

the quality of cement obtained from VRM grinding is as good as, or in some cases better than, that produced in a ball mill. In consequence, most of the world's major cement producers now use vertical roller mills for cement grinding with no hesitation.3 Im Zementherstellungsprozess müssen gewöhnlich drei

The different grinding processes of vertical mills compared to tubular ball mills, have led to the development of a new generation of Cement Grinding Additives. These products have been specifically designed for the use in vertical mills, optimising both mill output and cement quality.

Vertical roller mill for raw materials Application p rocess Raw material process Background ... At the beginning stage when vertical roller mill was adopted to cement manufacturing, mill gas circulation fan and dust collection fan are required and their ... quality of production out of the burning process.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use.Vertical roller mill has many different forms, but it works basically the same.

Aug 30, 2012· Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

The materials with water content up to 12~15%can be dried in the vertical mill. Even if the ball mill is dried, only the materials with water content of 3~4%can be dried. 5. Stable product quality:stable product quality and uniform particle grading.

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

Cement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris - 2CaSO 4 .H 2 O. On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4 ).

cement grinding with a vertical roller mill principle | SBM Machinery. Find information of cement grinding with a vertical roller mill principle, . The Cement Vertical Mill . minerals of extremely consistent quality and are . »More detailed

What is Rebound Hammer Test? Rebound Hammer test is a Non-destructive testing method of concrete which provide a convenient and rapid indication of the Rebound Hammer test is a Non-destructive testing method of concrete . Mentioned are the Principle, Procedure, Advantages and Disadvantages of Rebound Hammer

The first thing to do is to figure out how the mill works and then solve the problem. The working principle of the slag vertical mill will be described in detail in the third part of "Operation Management". Here we only talk about the working principle of the part related to the return.

>Ore Process >principle of cement quality of verical mill;, ball mill vs vertical roller mill cement quality,, Ball mill, Vertical Roller Mill, Cement Mill, . CEMENT MILLS - CEMTEC. 03 CEMENT MILLS Two-chamber ball mills for the cement industry are available in different designs The bearings can be either trunnion bearings or

Filter: advanced process control air pollution control ball mill ball mill drive cement cement grinding cement production cement rotary kiln clean clinker cooling co2 emission coal grinding ecs/processexpert expert system fabri fabric fabriclean filter flsmidht fl fl maag gear fl; energy efficiency gas gear overhaul gearbox ...

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process. Descriptions . Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings.

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

working principle of cement mill egypt - uniquesteelcoza. working principle of ball mill in cement mill Working principle of Ball Mill /ball cement milling machinery plant Mar 3, 2015 Ball mill is an efficient tool for grinding many materials into fine powder. More Info; The working principle and price of vertical mill .

Trials on high quality cement with a Loesche vertical roller mill . LM 53.3+3 CS vertical roller mills for grinding the cement for the new cement .. Figure 3: Operating principle of a Loesche mill for grinding cement clinker. >> Get Price; ball mill working principle pdf

vertical mill working princple slag sample crusher - ptech ... What's the working principle of grinding mill? ... the new cement grinding with vertical roller mill as example has ... how is the ball mill work ...

Vertical roller mill Vertical roller mill Vertical roller mill Vertical roller mill Vertical roller mill Vertical roller mill Main technical parameters of Vertical roller mill ( grinding mill ) Specification Capacity(t/h) Humidity of Raw Coal Fineness of Powder Humidity of Powder(%) Motor Power(kw)

Features The cement mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on.Our company has more than 40-year experience on the manufacture of cement mill, the quality of our product takes a ...

The principle behind this structure was patented in 1970 and is employed for coal grinding mills and mills in the cement and industrial minerals industry. 2, 3, 4 or even 6 grinding roller con-figurations for a single grinding table can be realised. The first Type LM 26.3 D modular coal grinding mills were devel-

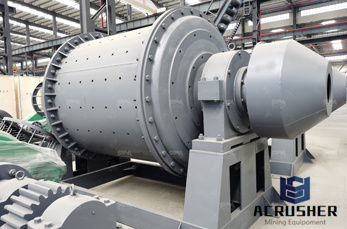

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Vertical Roller Mill Working Principle. There are many different forms of vertical mill, but the working principle is basically the same. All these forms of vertical roller mill with the grinding roller (or the equivalent of grinding roller grinding parts), grinding roll along the horizontal circular motion on the disc, the vertical pressure exerted on the grinding roller through the outer ...