WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Hot sale excellent professional best value cone vertical roller mill . Tags: Raymond Mill Vertical Mill 3 Roller Vertical Raymond Mill. Get Price Quartz Roller Mill. quartz roller mill. Sand Raymond Roller Machinery Quartz Grinding Machine Mill Price . hot sale Raymond Roller Mill for Stone,Granite,glass,etc Tags: Raymond Mill 4r3016 3 Roller ...

today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill

Vertical Roller Mill Manufacturers. Vertical roller mill is set crushing, grinding, drying, grading conveyor in one device, at the time of processing, its grinding capacity super material to the grinding operation to provide a guarantee

Nov 03, 2016· FL OK™ Mill, Vertical Roller Mill For Cement Grinding.

The inauguration of the world's largest vertical roller mill for cement grinding completes a smooth commissioning process at Shah Cement in Bangladesh.. Shah Cement Industries Ltd. of the Abul Khair Group is one of Bangladesh's largest cement producers. The FL vertical roller mill (VRM) was chosen to produce a full range of cement types at the Muktarpur Plant.

vertical grinding mill components - sistemasolarespa. how to get best output in vertical roller mill grinding; vertical turret milling made in china; types of vertical roller mills for raw grinding; vertical mill cement encyclopedia; frm ha long vertical mill; vertical roller mill cement grinding for sale made in europe; vertical cylidrical centerless grinding m c; impact crusher vertical dwg

Sep 18, 2012· LM vertical grinding mill is made up of feeding part, discharging part, gyre part, grinding table, decelerator, roller and so on. Stone Crushing Production Crusher used for aggregated rock producing divides to primary crushing, secondary crushing and stone sharping processing.

Working Principle of Vertical Roller Mill The grinding disc is driving by motor through reducer. The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers.

Sep 11, 2013· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to top-of-the-range installations. Special ...

Wide application of vertical roller mill in manganese ore milling. SBM Heavy Machinery Mining Machinery Co., Ltd. is a specialized manganese ore processing equipment and manganese ore crushing equipment provider. It provides a wide range of manganese ore crushers and manganese ore mills according to the customer's actual needs.

My Perl YaBB Forum - Vertical mill it's suitable for ..... vertical roller mill input and output get pretty incredible results, which also contributed to the final foreign cement vertical mill grinding ... vertical roller ...

Factors affecting the output and efficiency of vertical mills. Guide: In modern industrial production, vertical mills are used. Therefore, people are curious about the factors affecting the output and the quality of finished products.

Vertical roller mill adopts the principle of limited material bed grinding, grinding effect and therefore energy efficiency is greatly improved. According to statistics, more than milling roller mill grinding of raw materials can be saving 20% to 30%, grinding slag can save 30% to 40%, in foreign countries has been very widely used.

The vertical roller mill grinding machine is a traditional mill grinding technology update equipment, which can produce 80-600 mesh powders. The performance indexes can be greatly improved. The output of the TL50 mill increases by more than 40%, and the .

Hot Sale: Integrates drying, grinding, powder selection and conveying together Applied to the non-metallic ore, coal powder and slag powder three fields. Heavy Industry actively absorb successful abroad experience, and through the continuous technological innovation and upgrade of the R & D team, launched with independent intellectual property products: LM vertical mill.

LM vertical grinding mill is made up of feeding part, discharging part, gyre part, grinding table, decelerator, roller and so on. Stone Crushing Production Crusher used for aggregated rock producing divides to primary crushing, secondary crushing and stone sharping processing.

The anatomy of HLMX vertical mill. Grinding roller: Main component used for crushing and grinding materials. Together with the liner plate on the grinding plate, it can provide an effective grinding area. Grinding Plate: Component fixed on the output shaft of the reduction gear and where the grinding roller grinds materials.

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency.

Vertical roller mill are suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 9.3(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Vertical roller mill as pregrinding to ball mill Industrial Efficiency . To decrease the specific power consumption in finishing process or to increase the output of finish mill vertical roller mill as pregrinding to ball mill can also be introduced. Grinding capacity of finish mill increases about 30 60%. Vertical roller mill Wikipedia

The vertical roller mill grinding machine is a traditional mill grinding technology update equipment, which can produce 80-600 mesh powder. The performance indexes can be greatly improved. The output of the T-type mill is increased by more than 50%, and the .

factors affecting the output of vertical mill. The maximum life and value of a vertical roller mill can bring benefits to customs, how to get best output in vertical roller mill is a problem that many people care about. First, should konw several factors affecting the output of vertical mill.

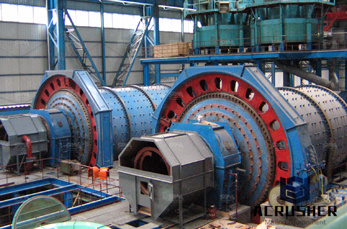

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

LUM Ultrafine Vertical Roller Mill is a kind of high yield of coal powder equipment, drying, grinding, powder selection, promotion in one, especially in the large grinding process, fully meet customer demand, SBM main technology, economic indicators have reached the international advanced level.